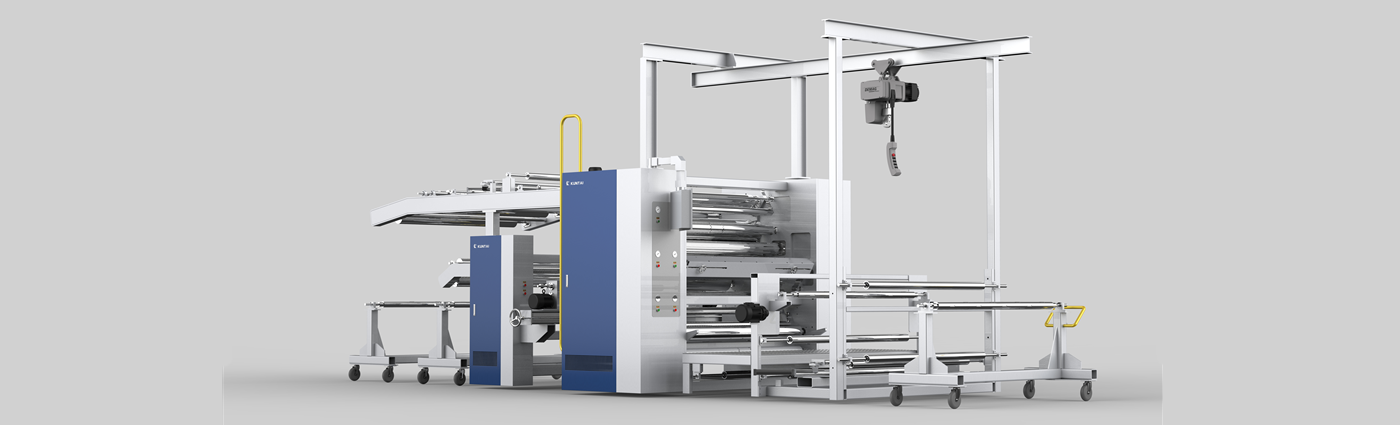

Waterproof Fabric Laminating Machine

In old days, people use coating technology to make waterproof fabric, while this method consumes much more chemical and also the final fabric is not breathable. One more reason why people nowadays do not like coating method is that it is not environmentally friendly. Therefore, more and more people choose to use waterproof fabric laminating machine to laminate fabric with waterproof film such as TPU film or PTFE film. This type of waterproof fabric laminating machine adopts glue dot transfer method which better preserves the breathability of the fabric itself and adds waterproof function to the final laminated fabric. Besides, people can use environmentally friendly and healthy hot melt PUR glue for laminating waterproof fabric.

- Product Description

- Specification

- Product Feature

- Related Application

Product Description

The main functions of waterproof and breathable fabrics are: waterproof, breathable, insulating, windproof, and warm. In terms of production process, the technical requirements for waterproof and breathable fabrics are much higher than those for general waterproof fabrics; From a quality perspective, waterproof and breathable fabrics also have functional characteristics that other waterproof fabrics do not possess. Waterproof and breathable fabric not only enhances the airtightness and water tightness of the fabric, but also has unique vapor permeability, which can quickly eliminate water vapor inside the structure, prevent mold growth, and keep the human body dry and comfortable. It perfectly solves the problems of breathability, windproof, waterproof, and warmth, and is a new type of healthy and environmentally friendly fabric.

In old days, people use coating technology to make waterproof fabric, while this method consumes much more chemical and also the final fabric is not breathable. One more reason why people nowadays do not like coating method is that it is not environmentally friendly. Therefore, more and more people choose to use waterproof fabric laminating machine to laminate fabric with waterproof film such as TPU film or PTFE film. This type of waterproof fabric laminating machine adopts glue dot transfer method which better preserves the breathability of the fabric itself and adds waterproof function to the final laminated fabric. Besides, people can use environmentally friendly and healthy hot melt PUR glue for laminating waterproof fabric.

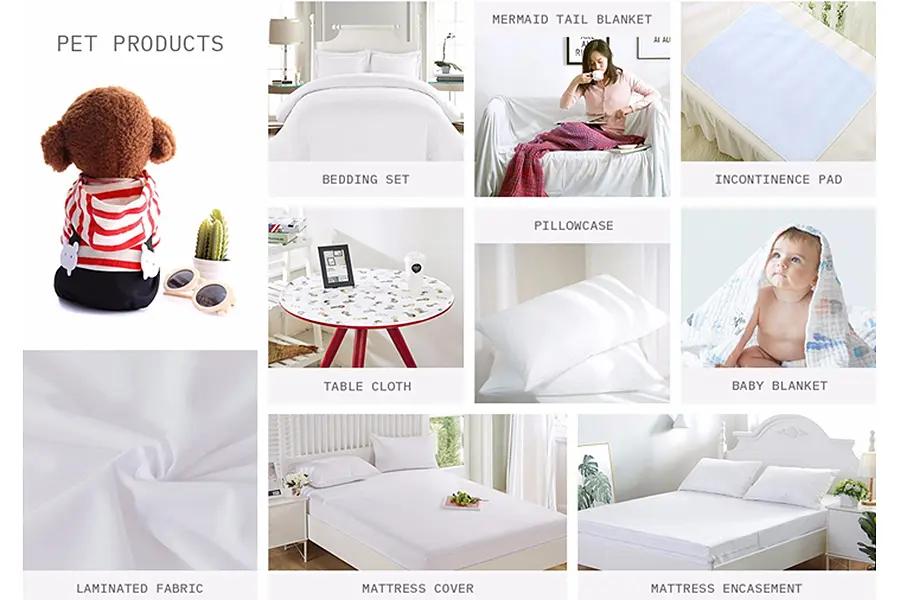

Due to above listed advantages of laminated waterproof fabric, waterproof fabric laminating machine is widely used in garment industry, home textile industry, car interior decoration industry, medical supplies, etc.

Kuntai makes all types of waterproof fabric laminating machines, catering to different customers' requirements. Some can use both solvent based PU glue and hot melt PUR glue; Some with knitted fabric feeding and tension control devices; Some can also laminate fabric and fabric in the same machine.

Specification

| Width | 1600mm, 1800mm, 2000mm, 3400mm, 3600mm, according to customers' requirement |

| Machine Speed | 20 to 70m/min |

| Gap Adjustment | Servo Motor Control |

| Heating Method | Oil Heater |

| CoolingDevice | Cooling Rollers, Chiller available on request |

| Machine Heating Power | 42-60kw, Customizable |

| Voltage | 220v, 380v, Customizable |

| Control system | Touch screen, PLC, servo motor |

| Varieties | a. Machine roller width b. Coating function c. Feeding methods d. Unwinding and rewinding methods |

Product Feature

-

1

Uniformly gluing/coating of waterproof film/membrane.

-

2

Hot melt adhesives makes possible environmental friendly products and realizes no pollution during the whole process of lamination.

-

3

Gluing gap and lamination gap can be digitally controlled.

-

4

Controlled by Programmable Logic Controller system with touch screen and modular designed structure, this machine can be easily and simply operated.

-

5

Famous brand motors, electrical parts, and inverters can be used for stable machine performance.

-

6

Good tension control makes laminated materials smooth and flat, free from bubles or wrinkles.

-

7

Various fabric and film openers feed materials smoothly and flatly.

-

8

For different fabric, different fabric conveyor and expanding devices are available for choice.

-

9

Low maintenance cost and less running noise.

-

10

If using blackout film in waterproof fabric laminating machine, blackout fabric can be generated..

-

11

For different application, different rewinding devices are available for choice.

-

12

Oil heater heating for uniform and energy saving heating.

Related Appliaction

application-3-7

water-based-glue-lamination-machine-16

Home

Home