Advanced PLC Control PUR Hot Melt Laminating Machine

Kuntai designs and manufactures a series of Advanced PLC Control PUR Hot Melt Laminating Machines, including standard compact PUR hot melt laminating machines, double usage PUR hot melt laminating machines and specific application customized PUR hot melt laminating machines.

Main features of advanced PLC Control PUR Hot Melt Laminating Machine: Automatic, Labor Saving, Precise Glue Quantity Control, Good Tension Control, Uniform Heating, Smooth Feeding.

- Product Description

- Specification

- Product Feature

- Related Application

Product Description

Generally speaking, hot melt adhesive come in two types: one is component solvent free nonreactive thermoplastic polymers and reactive thermoset pre-polymers. Both of these two types are widely used in textile finishing industry and advanced functional materials industry.

The most advanced hot melt adhesive, moisture reactive hot melt glue (PUR & TPU), is highly adhesive and environmentally friendly. It can be used for lamination of 99.9% textiles. The laminated material is soft and high temperature resistant. After moisture reaction, the material will not be easily affected by the temperature. Besides, with lasting elasticity, the laminated material is wear resistant, oil resistant and aging resistant. Especially, mist performance, neutral color and other various features of PUR makes medical industry application possible.

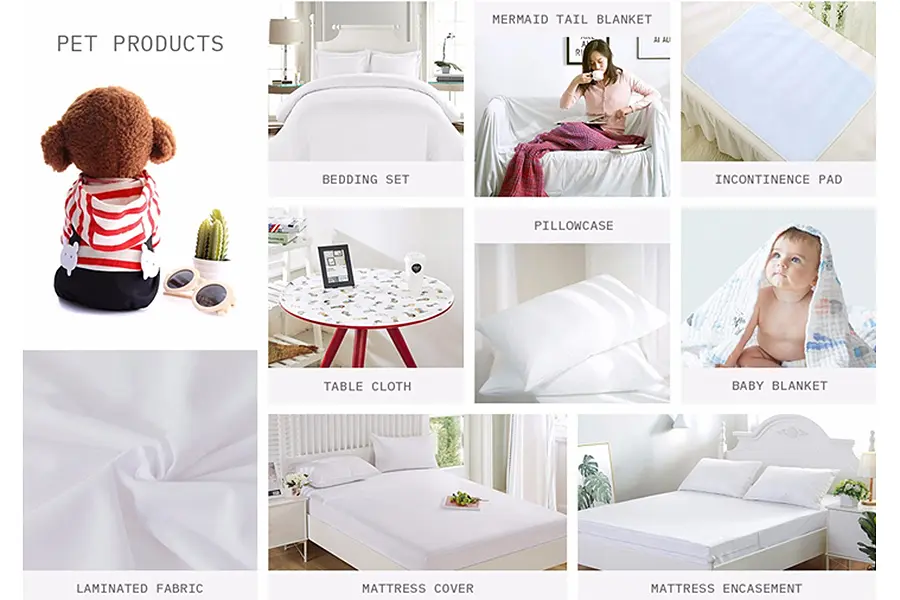

When PTFE, PE, TPU and other functional waterproof and breathable films are used in laminating, water-proof and heat preserving, waterproof and protective, oil & water & gas filteration and many other different new materials will be created. The demands of garment industry, home textile industry, motor manufacturing, medical industry, environment protection industry will be met. Nowadays most popular applications are laminating blackout film with curtain fabric for blackout curtain fabric and laminating sofa fabrics.

Our advanced PLC control hot melt lamination machine is mainly consisted of fabric rewinding and unwinding units, fabric and film drive systems and tension controller, film unwinding and lining or blackout film carrier rewinding device, hot melt glue melting unit (optional), pump (optional), conduction oil source system (optional), glue dot transfer unit, laminating device, cooling device, PLC, tension control devices and other devices. It is compact, highly automatic and easy to maintain. We make all types of machine designs as per specific application requirements. For jersey, elastic, sponge, etc, we make advanced PLC control hot melt laminating machines with various types of feeding methods for both materials in rolls or in sheets and accumulators.

Specification

| Width | 1600mm, 1800mm, 2000mm, 3400mm, 3600mm, according to customers' requirement |

| Machine Speed | 20 to 70m/min |

| Gap Adjustment | Servo Motor Control |

| Heating Method | Oil Heater/Boiler |

| CoolingDevice | Cooling Rollers, Chiller available on request |

| Machine Heating Power | 42-60kw, Customizable |

| Voltage | 220v, 380v, Customizable |

| Control system | Touch screen, PLC, servo motor |

| Varieties | a. Machine roller width b. Coating function c. Feeding methods d. Unwinding and rewinding methods |

Product Feature

-

1

Uniformly gluing/coating of hot melt glue onto textiles, nonwoven materials, foam, film/membrane, velevt, chenille, blanket,etc.

-

2

Hot melt adhesives contribute to possible environmental friendly products and realizes no pollution lamination.

-

3

Precise gluing gap and lamination gap control

-

4

Controlled by PLC system with touch screen and modular designed structure, this PUR hot melt lamination machine can be operated in a simple and easy way.

-

5

International brand parts like Siemens motors, Schneider electrical parts, and Yaskawa inverters can be used for stable machine performance.

-

6

Good tension control makes laminated materials smooth and flat, guaranteeing good bonding effect.

-

7

Various fabric and film openers guarantees smooth and orderly feeding.

-

8

For different fabric, different fabric conveyor and expanding devices can be chosen.

-

9

Low maintenance cost and less running noise.

-

10

When it is applied in lamination of functional waterproof moisture permeable films such as PTFE,PE and TPU, more materials which are waterproofing and insulated, waterproof and protective will even be invented. This makes PUR hot melt lamination machine widely used in mattress protector, outdoor jackets, blackout curtain, etc.

-

11

For different application, different rewinding devices (small roll rewinder and large batch rewinder) are available for choice.

Related Appliaction

application-3-7

water-based-glue-lamination-machine-16

Home

Home