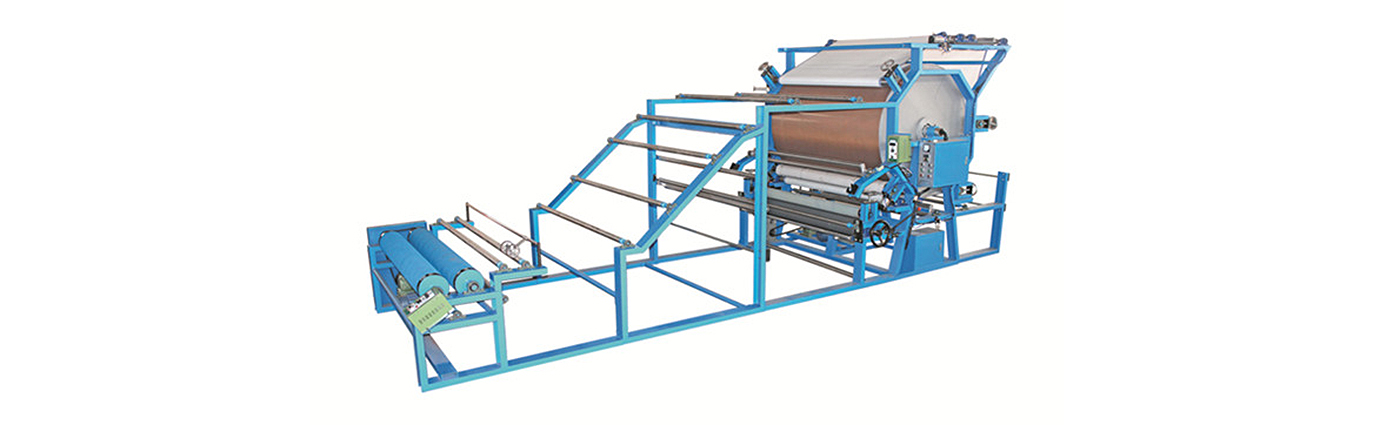

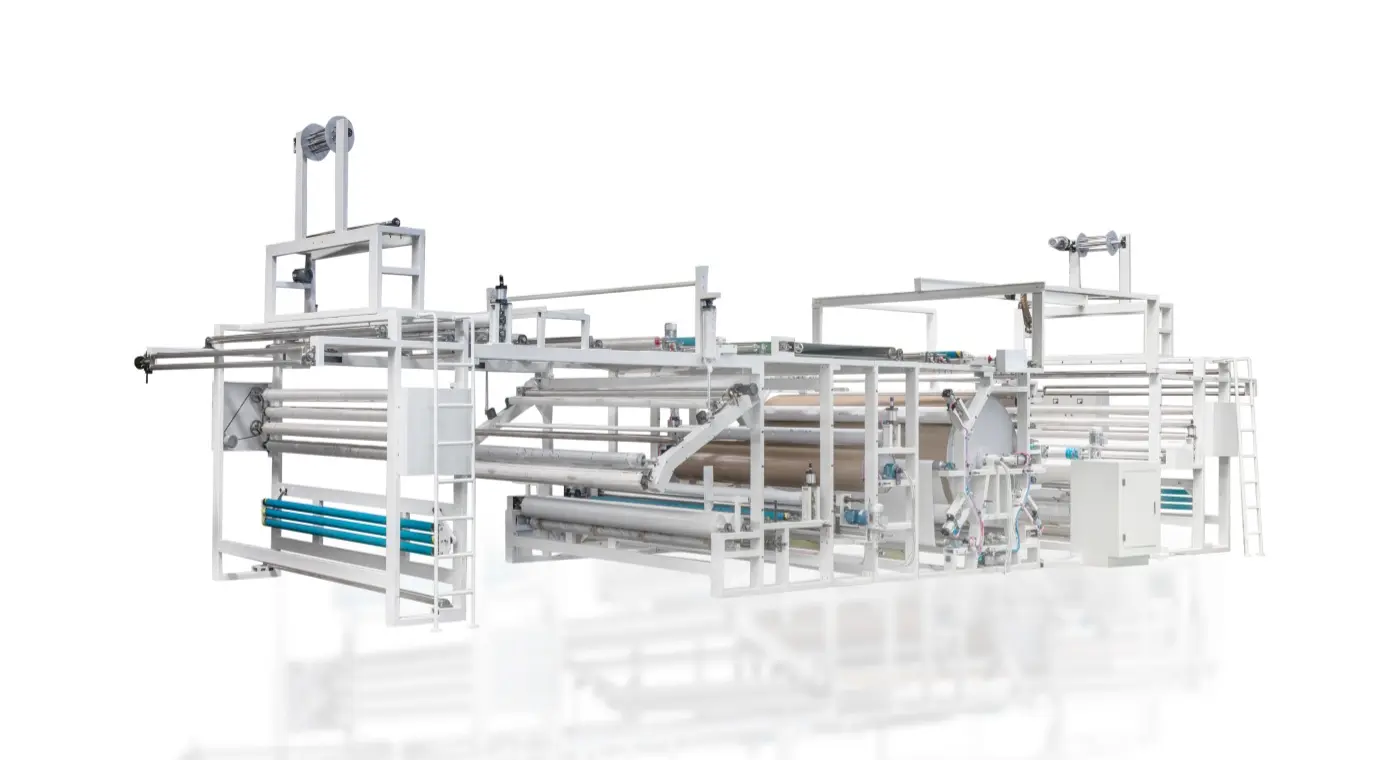

Best Laminating Machine for Sofa Fabric

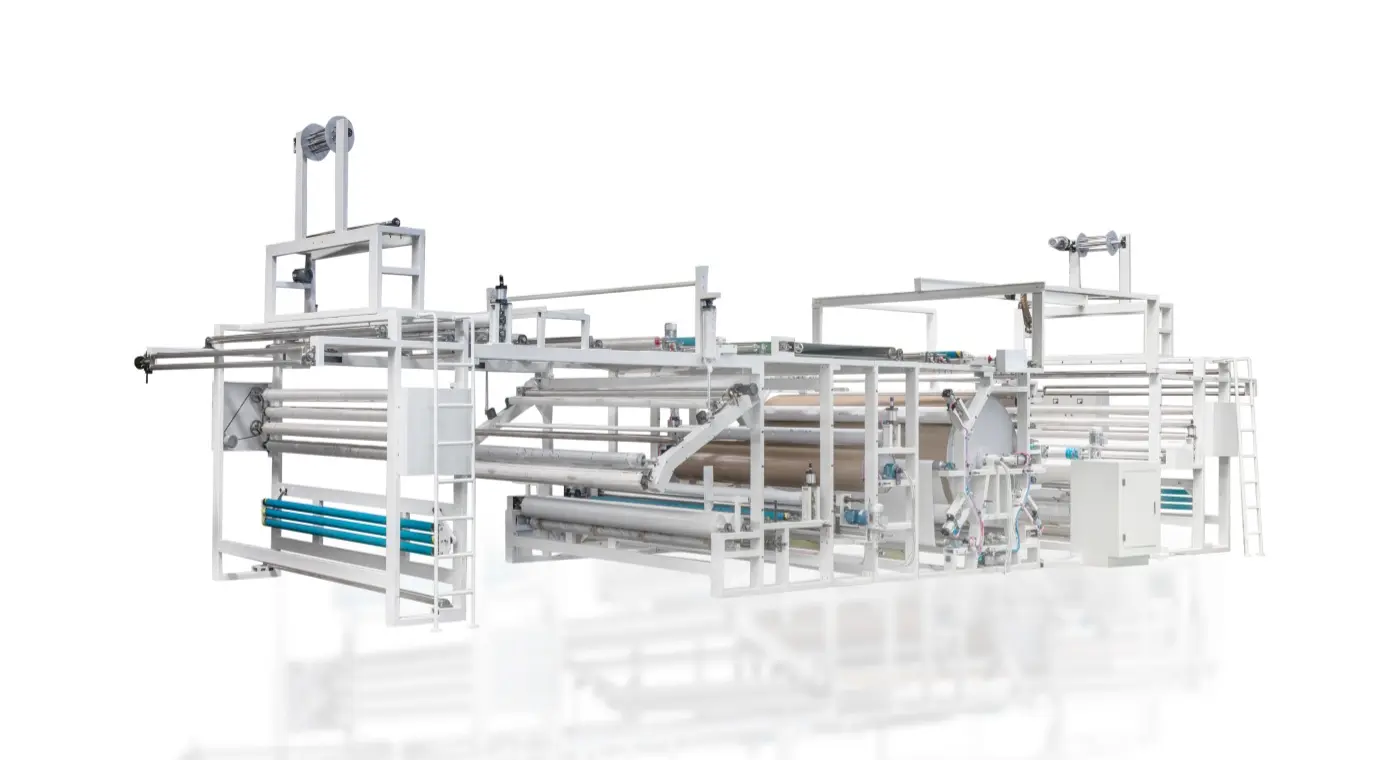

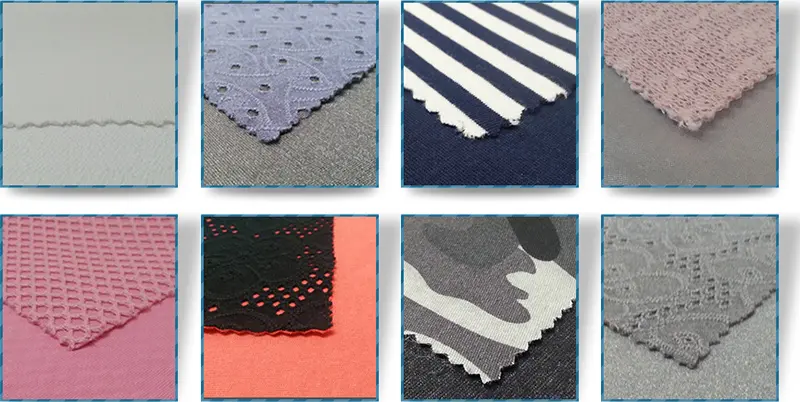

Year 2025 most popular and best laminating machine for sofa fabric can laminate velvet, chenille, woven, polyester and all types of sofa fabrics. You can use either hot melt PUR glue or solvent based glue on this sofa fabric laminating machine.

Bubble free, crease free, strong bonding sofa fabric laminating machine.

- Product Description

- Specification

- Product Feature

- Related Application

Product Description

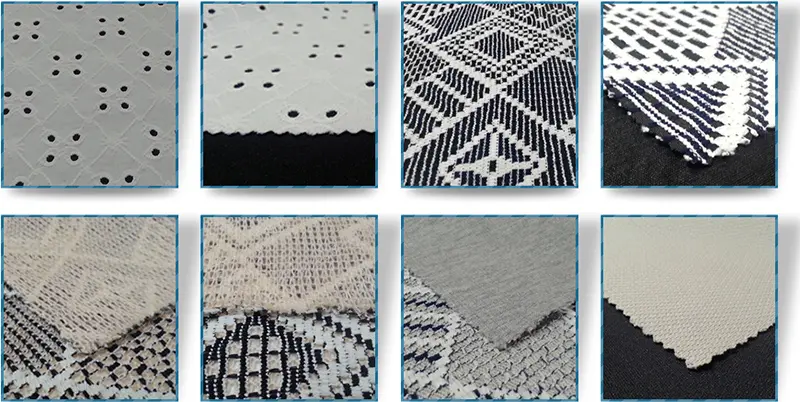

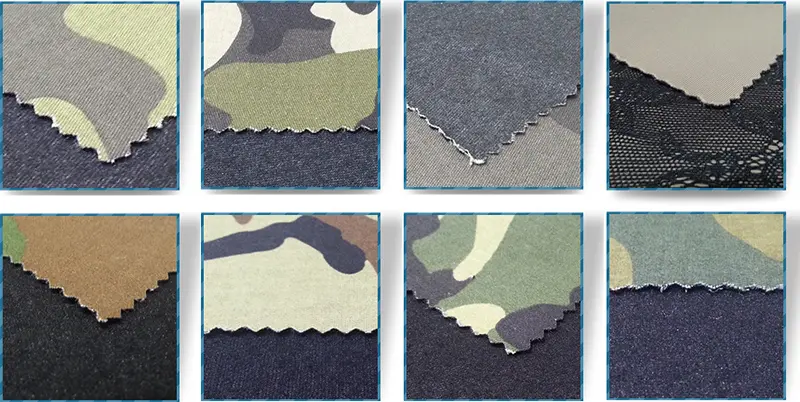

Nowadays sofa fabrics are complicated. It can be chenille or velvet or fleece or any other fabrics. Therefore sofa fabric laminating machine should be versatile and capable of laminating all these different type of fabrics and feed them smoothly and in order and treat the fabrics properly without harm the original fabric features.

Besides the complexity of the fabrics types, there is another issue about the glue type for sofa fabric laminating machine. Previously most customers use solvent based glue, while nowadays due to more and more strict control over environmental friendship, more and more composite laminating factories like hot melt PUR glue. Under this situation, Kuntai designs and manufactures various types of laminating machines for sofa fabric. This year, the most popular type sofa fabric laminating machine is the laminating machine which can use both hot melt PUR glue and solvent based glue.

Kuntai can equip this series of laminating machine for sofa fabric with various types of feeding devices, tension control devices, spreading and opening devices, pressing laminating methods, cooling devices, accumulating designs, rewinding mechanisms, etc to realize different users operation requirements.

Specification

| Max Material Width | 1200mm, 1600mm, 1800mm, 2400mm, 3200mm, 3400mm, according to customers' requirement |

| Machine Roller Width | 1400mm, 1800mm, 2000mm, 2600mm, 3400mm, 3600mm, according to customers' requirement |

| Machine Speed | 5-70m/min, according to customers' requirement |

| Gap Adjustment | Servo Motor Control Available on Request |

| Heating Method | Electrical and Oil Heating or Only Oil Heating, etc |

| Cooling Method | Cooling fan, cooling rollers, chiller, as per customers’ request |

| Voltage | 220v, 380v, Customizable |

| Control system | PLC, Servo Motor, Inverter |

| Varieties | a. With or without coating function b. Different unwinding stands c. Different feeding devices d. Double layers or trilayers lamination |

Product Feature

-

1

Multifunctional, able to use solvent based glue, hot melt film/web, hot melt glue, water based glue (thickener added).

-

2

Highly productive.

-

3

Energy saving.

-

4

If needed, compact machine design can be customized as per your factory space layout.

-

5

Careful feeding, spreading, conveying, pressing, cooling and other treatments of material during process, catering to each fabric features.

-

6

KUNTAI designs a number of different gluing devices based on fabric feature and final product requirements.

-

7

Precise data strength control over machines. That is why KUNTAI can make high quality stable laminating machine with 3400mm, 3600mm, 5200mm or wider roller width.

-

8

For strechable knitted fabric, such as mattress fabric, garment fabric, KUNTAI adopts special tension control system and conveyoring system, so that the fabrics feed in order.

Related Appliaction

water-based-glue-lamination-machine-7

water-based-glue-lamination-machine-11

water-based-glue-lamination-machine-12

Home

Home