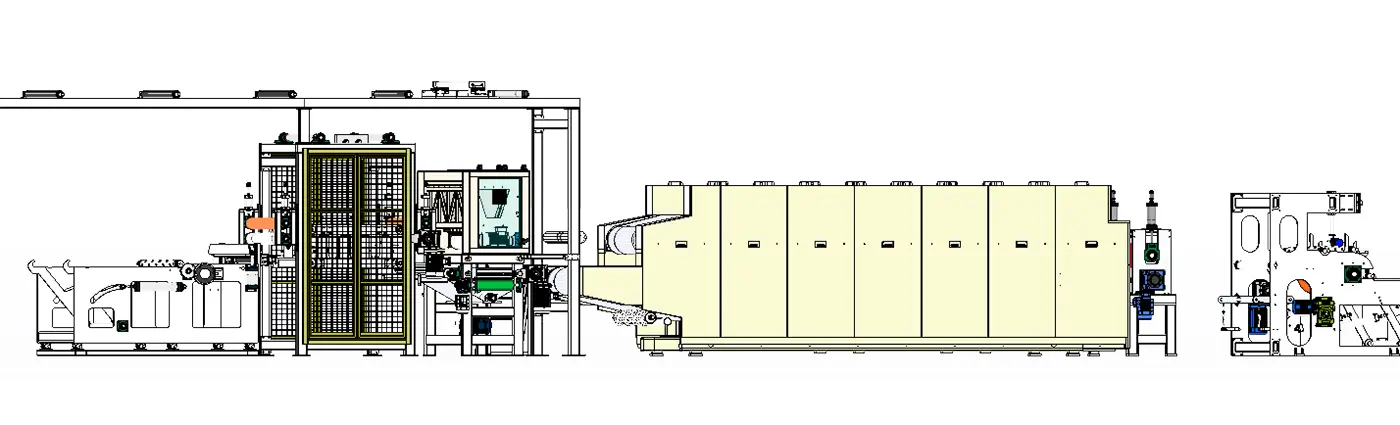

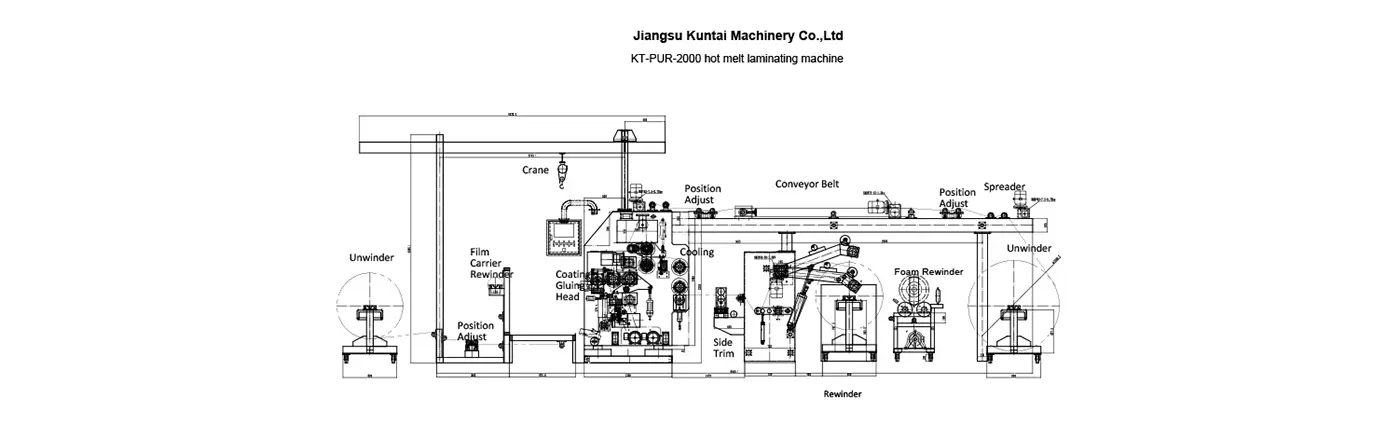

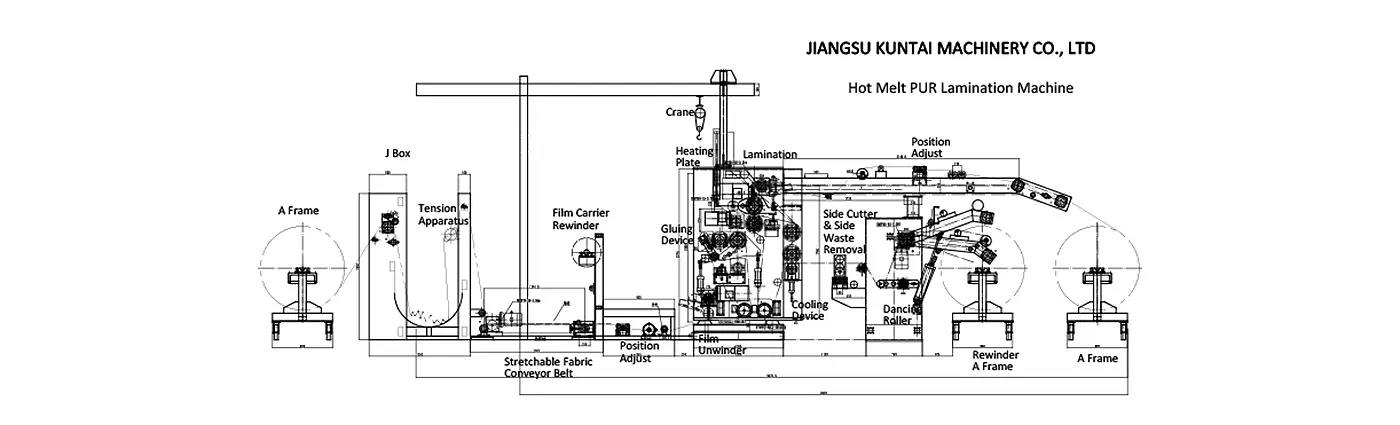

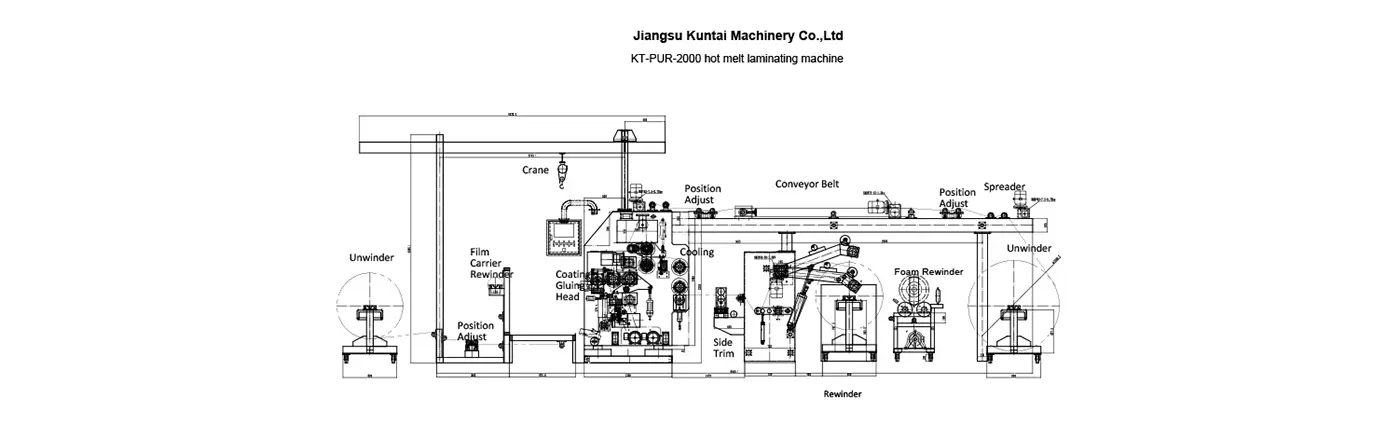

Multipurpose Coating Lamination Machine

Multipurpose coating lamination machine with coating and gluing lamination function.

- Product Description

- Specification

- Product Feature

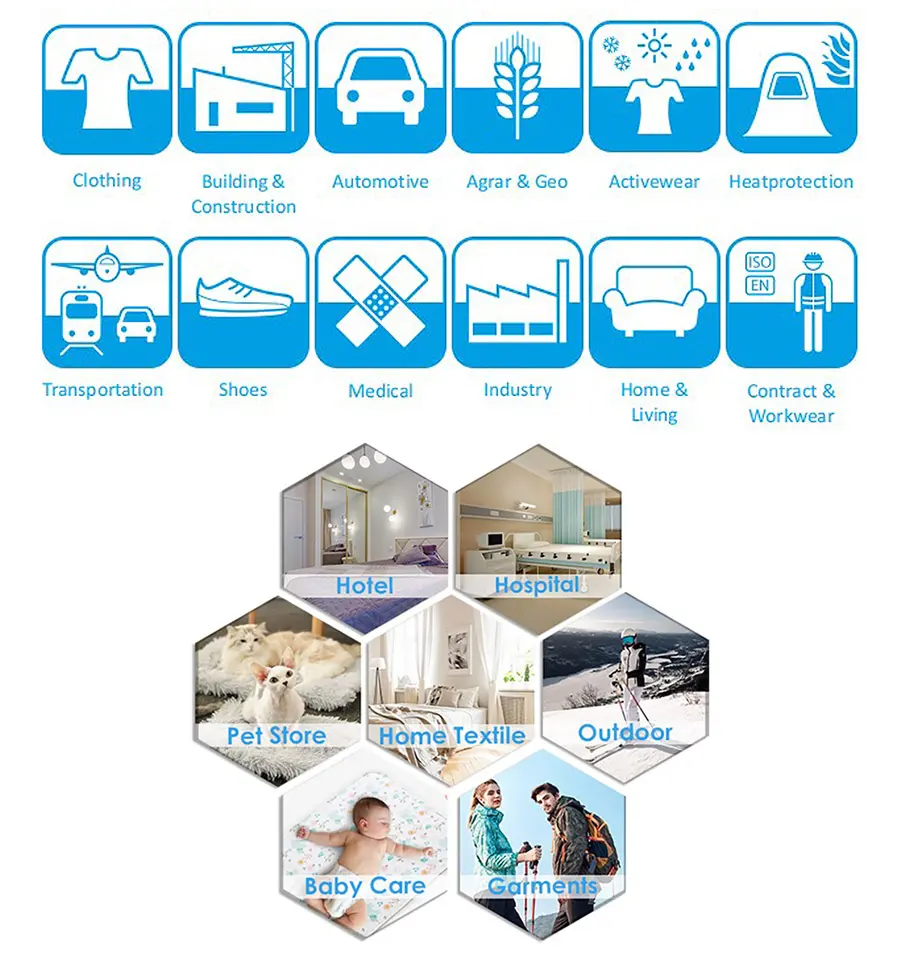

- Related Application

Product Description

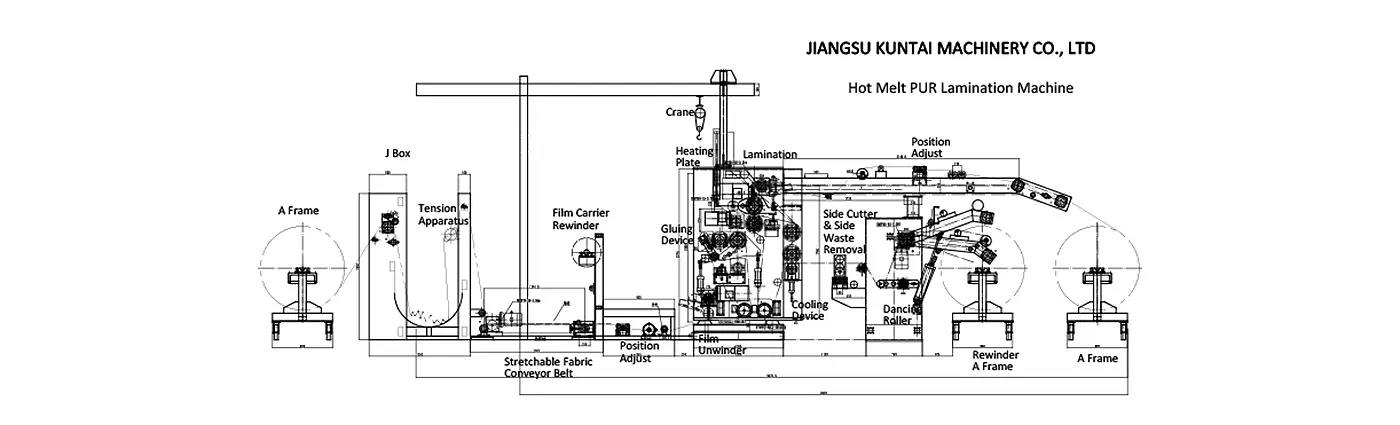

Laminating with hot melt adheisves traces back to 1990. KUNTAI is the forerunner in this technology in China, with technology cooperating partners in Germany and Italy. Kuntai develops, designs, manufactures and supplies hotmelt coating and laminating lines with rotogravure, rotary screen and roller coating heads.

With nearly decades of experience, KUNTAI provides our customers with application catered design, high quality hot melt coating lamination machine, timely and satisfactory aftersales service and updating technology support.

There are no solvents used in KUNTAI hot melt coating lamination.

The multi roller coating system is suitable to achieve an overall, compact coating on a textile or non-textile substrate.

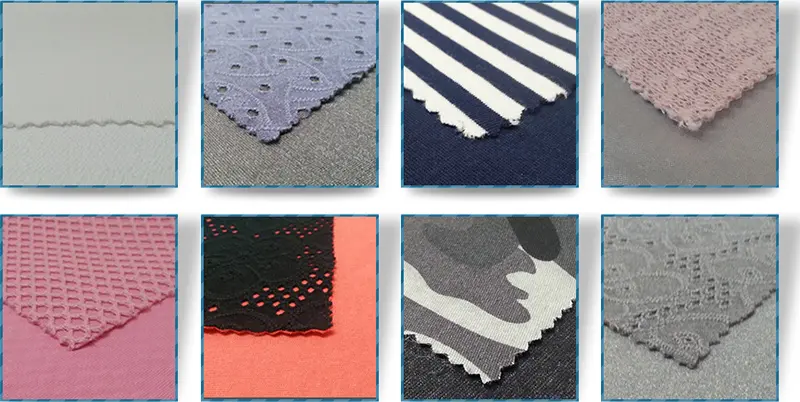

Almost all kinds of lamination of different materials such as woven or knitted fabrics, nonwoven, artificial leather, papers and foils/films/membranes are possible on this series of hot melt coating lamination machine.

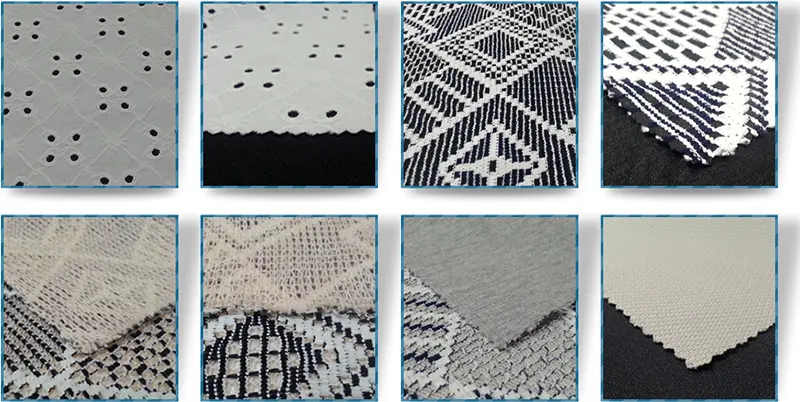

For coatings and laminations where softness and elasticity of the laminate is of lesser importance, a variety of net shaped or lined patterns are also applied.

Specification

| Max Material Width | 1200mm, 1600mm, 1800mm, 2400mm, 3200mm, 3400mm, according to customers' requirement |

| Machine Roller Width | 1400mm, 1800mm, 2000mm, 2600mm, 3400mm, 3600mm, according to customers' requirement |

| Machine Speed | 5-70m/min, according to customers' requirement |

| Gap Adjustment | Servo Motor Control |

| Heating Method | Oil Heating |

| Cooling Method | Cooling fan, cooling rollers, chiller, as per customers’ request |

| Voltage | 220v, 380v, Customizable |

| Control system | PLC, Servo Motor |

| Varieties | a. With or without coating function b. Different unwinding stands c. Different feeding devices d. Double layers or trilayers lamination |

Product Feature

-

1

Versatility of application.

-

2

High production possibility.

-

3

Environmentally friendly, emission-free process, no vapors, aerosols, fumes.

-

4

Low specific energy consumption.

-

5

If needed, compact machine design has small floor space requirement for production line.

-

6

High precision of hotmelt application and easy reproducibility, thus rendering a high process efficiency.

-

7

Use of hotmelt compounds in different forms, no grinding costs, moderately priced optimized adhesive compounds can be used.

-

8

Careful treatment of material during process, catering to high end market products.

-

9

KUNTAI designs a number of standardized dot patterns that are suitable for the process depending on material type and final product.

-

10

Computerized the strength control over machines. That is why KUNTAI can make high quality hot melt PUR lamination machine with 3400mm or wider roller width.

-

11

For strechable fabric, such as mattress fabric, garment fabric, KUNTAI uses unique tension control system and conveyor system, so that the fabrics feed in order.

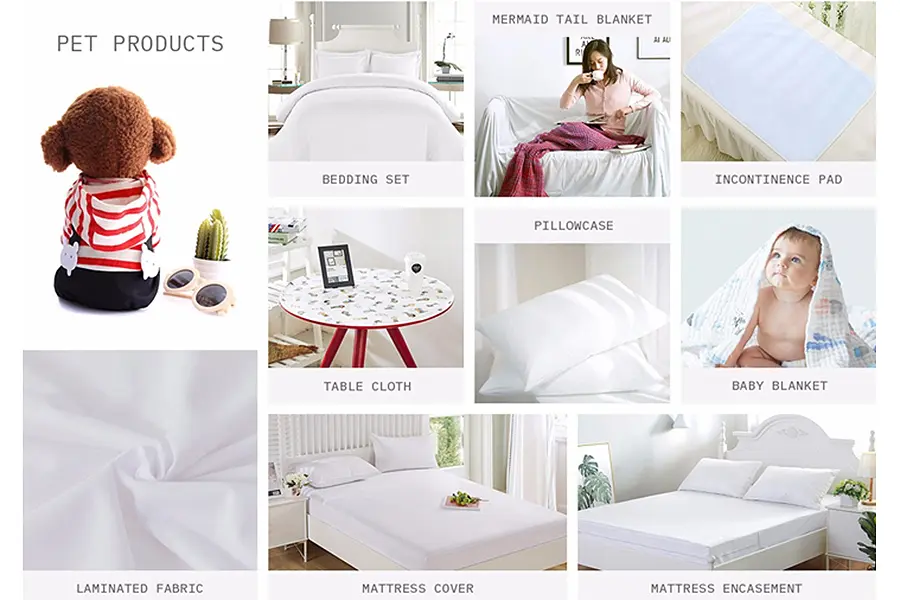

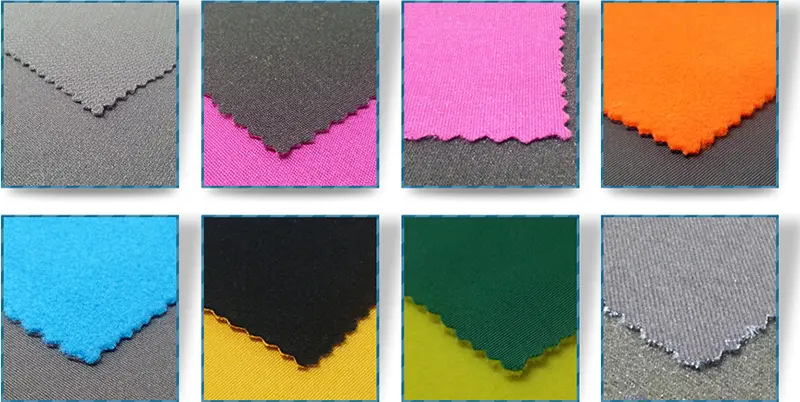

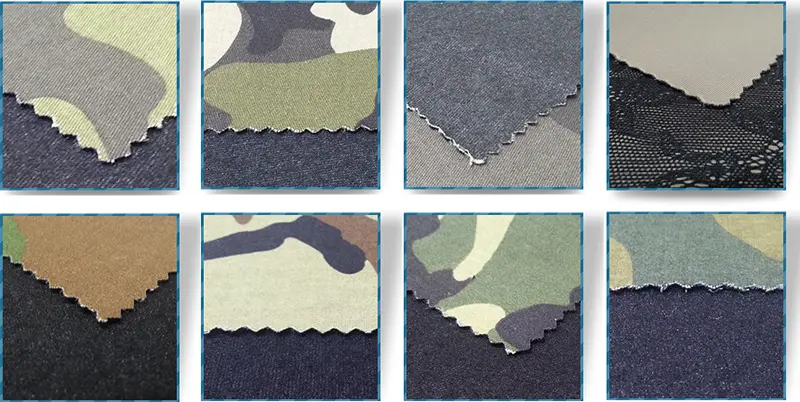

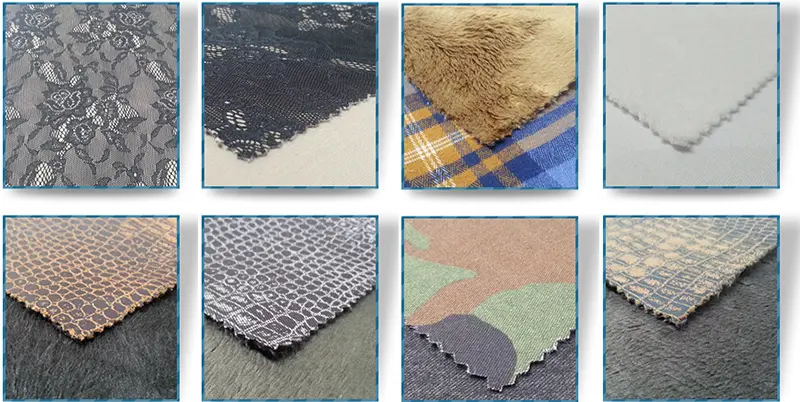

Related Appliaction

water-based-glue-lamination-machine-14

water-based-glue-lamination-machine-11

water-based-glue-lamination-machine-7

water-based-glue-lamination-machine-10

water-based-glue-lamination-machine-17

water-based-glue-lamination-machine-16

water-based-glue-lamination-machine-13jpg

water-based-glue-lamination-machine-8

water-based-glue-lamination-machine-9

water-based-glue-lamination-machine-19

water-based-glue-lamination-machine-12

Home

Home