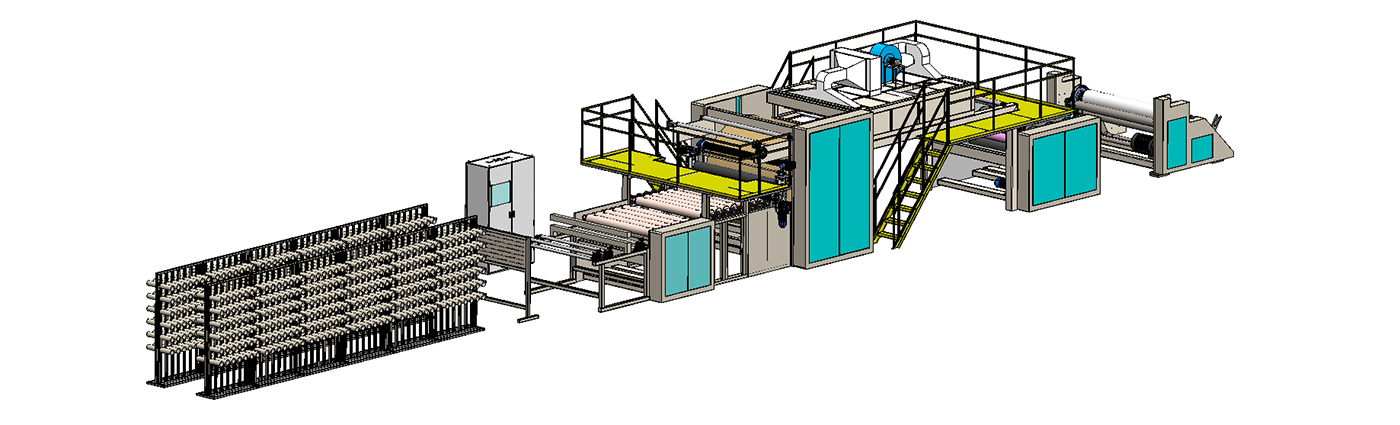

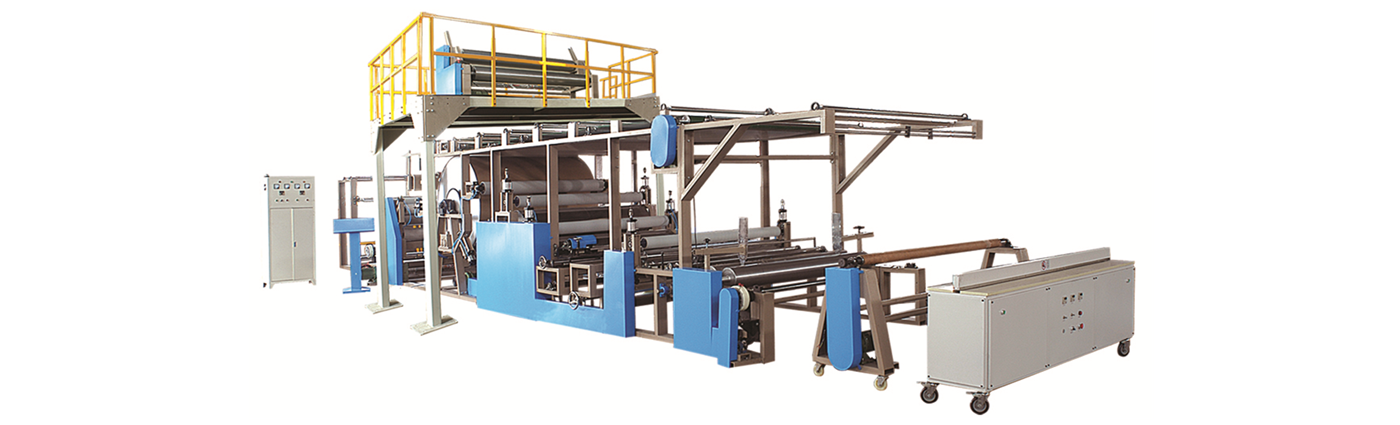

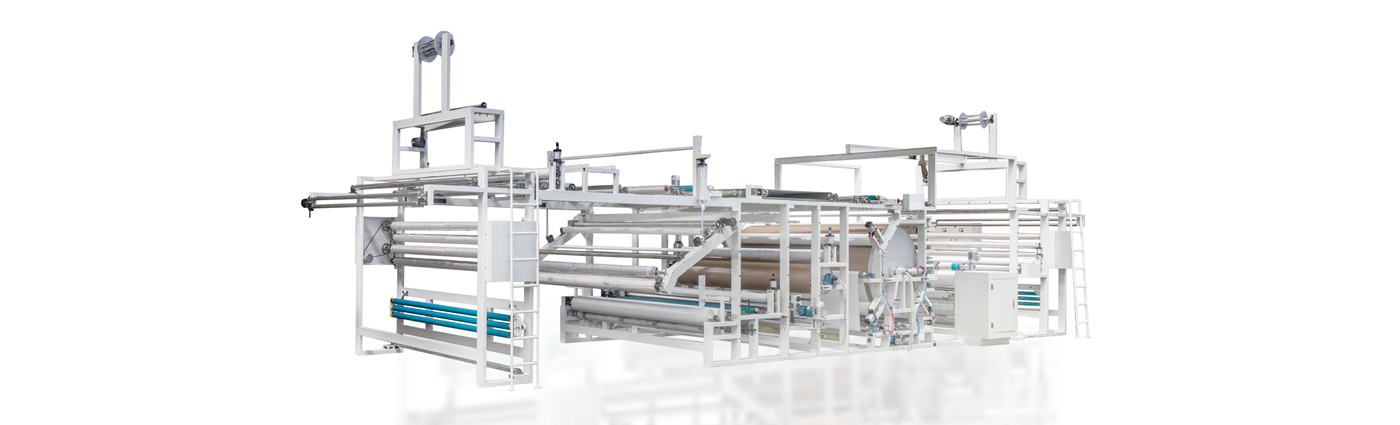

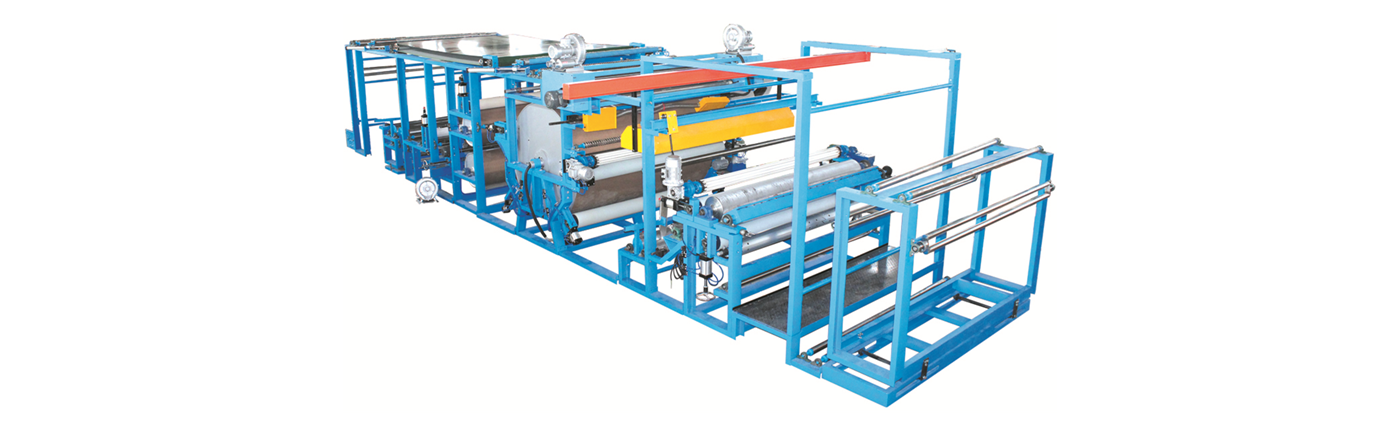

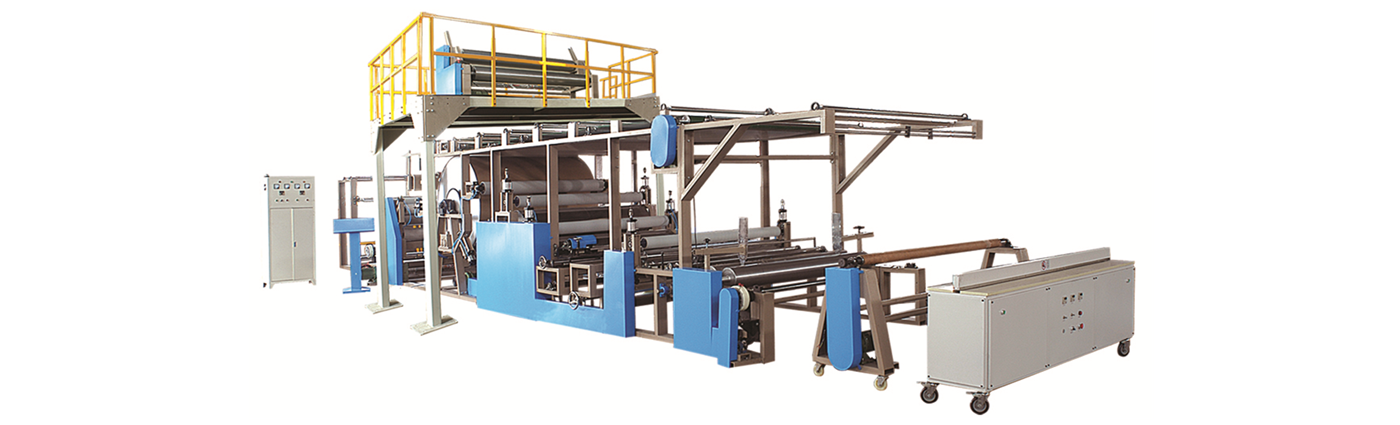

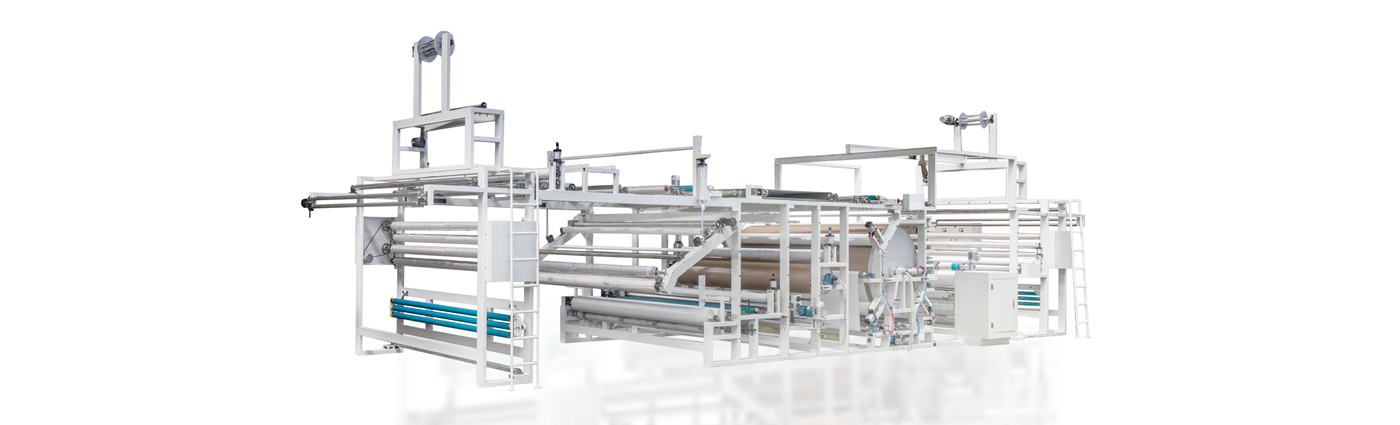

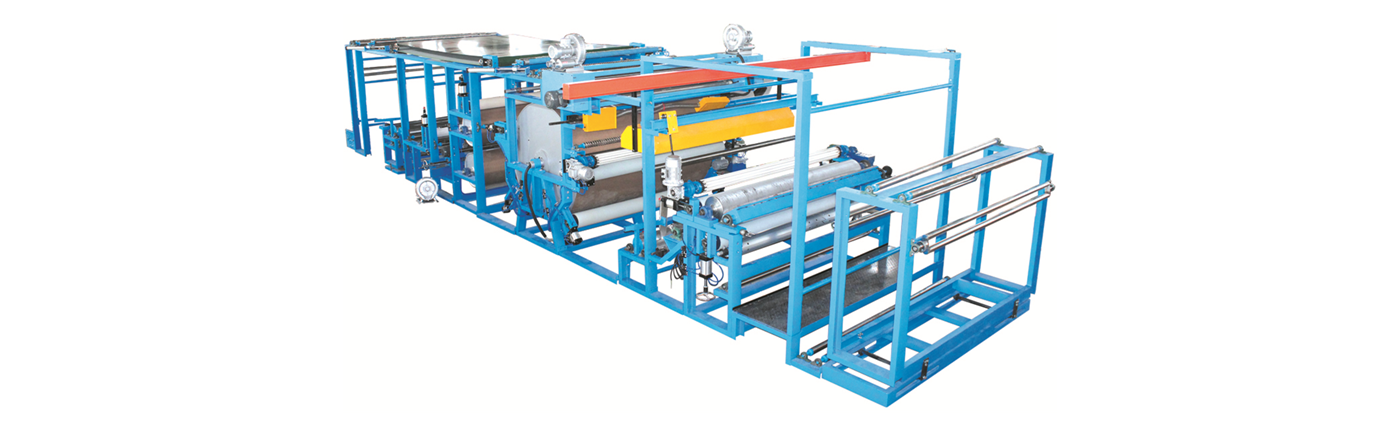

PU Glue Lamination Machine

PU Glue Lamination Machine for Laminating Fabric, Foam, EVA, Nonwoven, Felt, Artificial Leather, etc using Solvent Based Glue. This type of lamination machine is widely used in sofa fabric, garment industry and many other areas.

- Product Description

- Specification

- Product Feature

- Related Application

Product Description

PU glue lamination machine is still one of the choices for lamination, though more and more countries and users know PU glue is not healthy and smelly. Especially, in certain applications, no other type of glues can surpass the function of PU glue, either in bonding capacity or lasting effect under certain environmental situations.

Compared with hot melt PUR lamination machine, PU glue lamination machine is more economical, because this type of glue does not need melter or heating system for gluing devices.

Compared with water based glue lamination machine, PU glue lamination machine laminated product has higher bonding strength and more lasting effect under severe environmental situations.

Kuntai can equip this series of lamination machine with various types of feeding devices, tension control devices, spreaders and openers, pressing laminating methods, cooling devices, accumulating designs, rewinding mechanisms, etc catering to various different fabrics or other materials.

Specification

| Width | 1200mm, 1600mm, 1800mm, 2400mm, 3200mm, 5000mm, according to customers' requirement |

| Machine Speed | 5-70m/min, according to customers' requirement |

| Gap Adjustment | As per materials max thickness |

| Heating Method | Electrical and Oil Heating or Only Oil Heating, etc |

| Cooling Method | Cooling fan, cooling rollers, chiller, as per customers’ request |

| Max Heating Temperature | 180 celcius degree, 200 celcius degree, 250 celcius degree, as per application requirements |

| Machine Heating Power | 120-380kw, Customizable |

| Voltage | 220v, 380v, Customizable |

| Control system | Touch screen, PLC, servo motor, inverter |

| Varieties | a.With or without water based glue gluing device b.Different unwinding stands c.Different feeding devices d.Double layers or trilayers lamination |

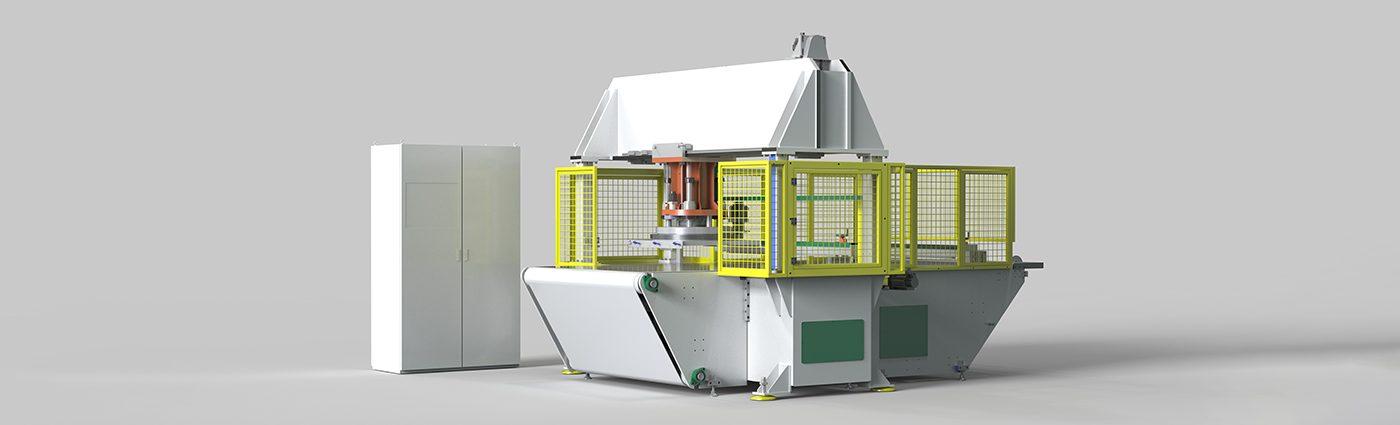

Product Feature

-

1

IVersatility of function, capable of using PU glue, water based glue (thickener added).

-

2

Possible designs for high productivity and continuous labor saving operation.

-

3

Low power consumption possible.

-

4

Smooth feeding, spreading, conveying, pressing, cooling and other treatments of material during lamination process, catering to each fabric or materials features or final products requirements.

-

5

KUNTAI designs a number of customized gluing rollers for PU glue lamination machine, suitable for each application requirements, such as garment, sofa fabric, home textile, flooring, etc.

-

6

Computerized the strength control over machines. That is why KUNTAI can make high quality long service life lamination machine with 3400mm, 3600mm, 5200mm or even wider roller width.

-

7

Raw materials saving, precise position, faster speed, stable structure

-

8

For strechable fabric, such as mattress fabric, garment fabric, KUNTAI can adopt various tension control systems and conveyor systems, so that the fabrics feed without wrinkles and with fewer workers needed in operation.

-

9

Higher automation

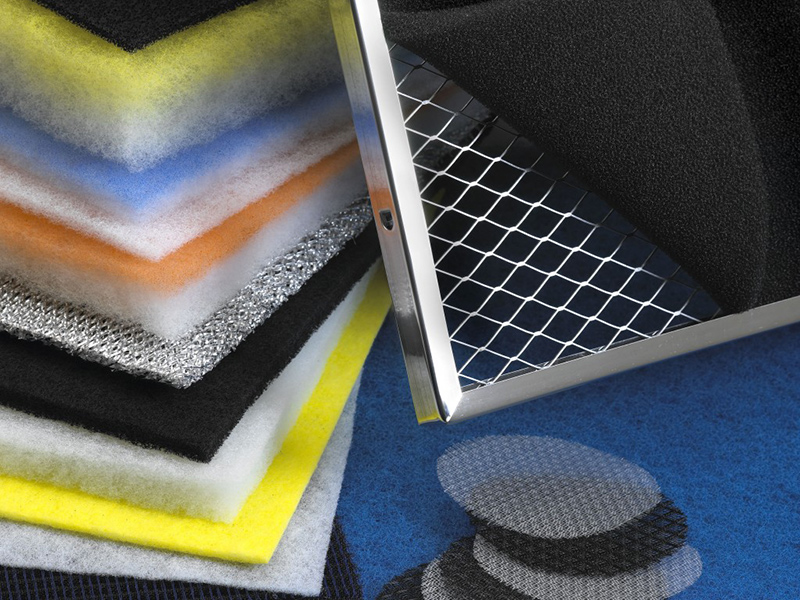

Related Appliaction

Automotive assembly

Active wear(outdoor)

Construction, for both materials in rolls or in sheets

Home textile industry

Automotive assembly

Protective safety clothes, including defence wear

Automotive assembly

Interlining for clothing and shoe industry

Frequently Asked Questions

-

What is the fiber coupling based on Single Emitter Diode Lasers?

+The profile of common free output diode lasers is asymmetric (elliptic) Gaussian beam with a large divergence and nonuniform distribution. In most applications, it is necessary to shape and smooth the beam,there are two common shaping methods: optical lens shaping and fiber coupling shaping. Using lens could change the beam spot to rectangle but could not make it uniform , the space location for lens could not be removed flexibly. Using fibers, the output beam profile is rounded and uniform, the beam quality could improved, and the fiber coupling is an important means to realize flexible transmission which is popular in Medical, Industry areas. BWT Beijing has focused on fiber coupling diode lasers for over 15 years, and became the famous and professional manufacturers in international.

-

What is the fiber coupling based on Single Emitter Diode Lasers?

+The profile of common free output diode lasers is asymmetric (elliptic) Gaussian beam with a large divergence and nonuniform distribution. In most applications, it is necessary to shape and smooth the beam,there are two common shaping methods: optical lens shaping and fiber coupling shaping. Using lens could change the beam spot to rectangle but could not make it uniform , the space location for lens could not be removed flexibly. Using fibers, the output beam profile is rounded and uniform, the beam quality could improved, and the fiber coupling is an important means to realize flexible transmission which is popular in Medical, Industry areas. BWT Beijing has focused on fiber coupling diode lasers for over 15 years, and became the famous and professional manufacturers in international.

-

What is the fiber coupling based on Single Emitter Diode Lasers?

+The profile of common free output diode lasers is asymmetric (elliptic) Gaussian beam with a large divergence and nonuniform distribution. In most applications, it is necessary to shape and smooth the beam,there are two common shaping methods: optical lens shaping and fiber coupling shaping. Using lens could change the beam spot to rectangle but could not make it uniform , the space location for lens could not be removed flexibly. Using fibers, the output beam profile is rounded and uniform, the beam quality could improved, and the fiber coupling is an important means to realize flexible transmission which is popular in Medical, Industry areas. BWT Beijing has focused on fiber coupling diode lasers for over 15 years, and became the famous and professional manufacturers in international.

-

What is the fiber coupling based on Single Emitter Diode Lasers?

+The profile of common free output diode lasers is asymmetric (elliptic) Gaussian beam with a large divergence and nonuniform distribution. In most applications, it is necessary to shape and smooth the beam,there are two common shaping methods: optical lens shaping and fiber coupling shaping. Using lens could change the beam spot to rectangle but could not make it uniform , the space location for lens could not be removed flexibly. Using fibers, the output beam profile is rounded and uniform, the beam quality could improved, and the fiber coupling is an important means to realize flexible transmission which is popular in Medical, Industry areas. BWT Beijing has focused on fiber coupling diode lasers for over 15 years, and became the famous and professional manufacturers in international.

-

What is the fiber coupling based on Single Emitter Diode Lasers?

+The profile of common free output diode lasers is asymmetric (elliptic) Gaussian beam with a large divergence and nonuniform distribution. In most applications, it is necessary to shape and smooth the beam,there are two common shaping methods: optical lens shaping and fiber coupling shaping. Using lens could change the beam spot to rectangle but could not make it uniform , the space location for lens could not be removed flexibly. Using fibers, the output beam profile is rounded and uniform, the beam quality could improved, and the fiber coupling is an important means to realize flexible transmission which is popular in Medical, Industry areas. BWT Beijing has focused on fiber coupling diode lasers for over 15 years, and became the famous and professional manufacturers in international.

-

What is the fiber coupling based on Single Emitter Diode Lasers?

+The profile of common free output diode lasers is asymmetric (elliptic) Gaussian beam with a large divergence and nonuniform distribution. In most applications, it is necessary to shape and smooth the beam,there are two common shaping methods: optical lens shaping and fiber coupling shaping. Using lens could change the beam spot to rectangle but could not make it uniform , the space location for lens could not be removed flexibly. Using fibers, the output beam profile is rounded and uniform, the beam quality could improved, and the fiber coupling is an important means to realize flexible transmission which is popular in Medical, Industry areas. BWT Beijing has focused on fiber coupling diode lasers for over 15 years, and became the famous and professional manufacturers in international.

Home

Home